Knit Line Injection Molding

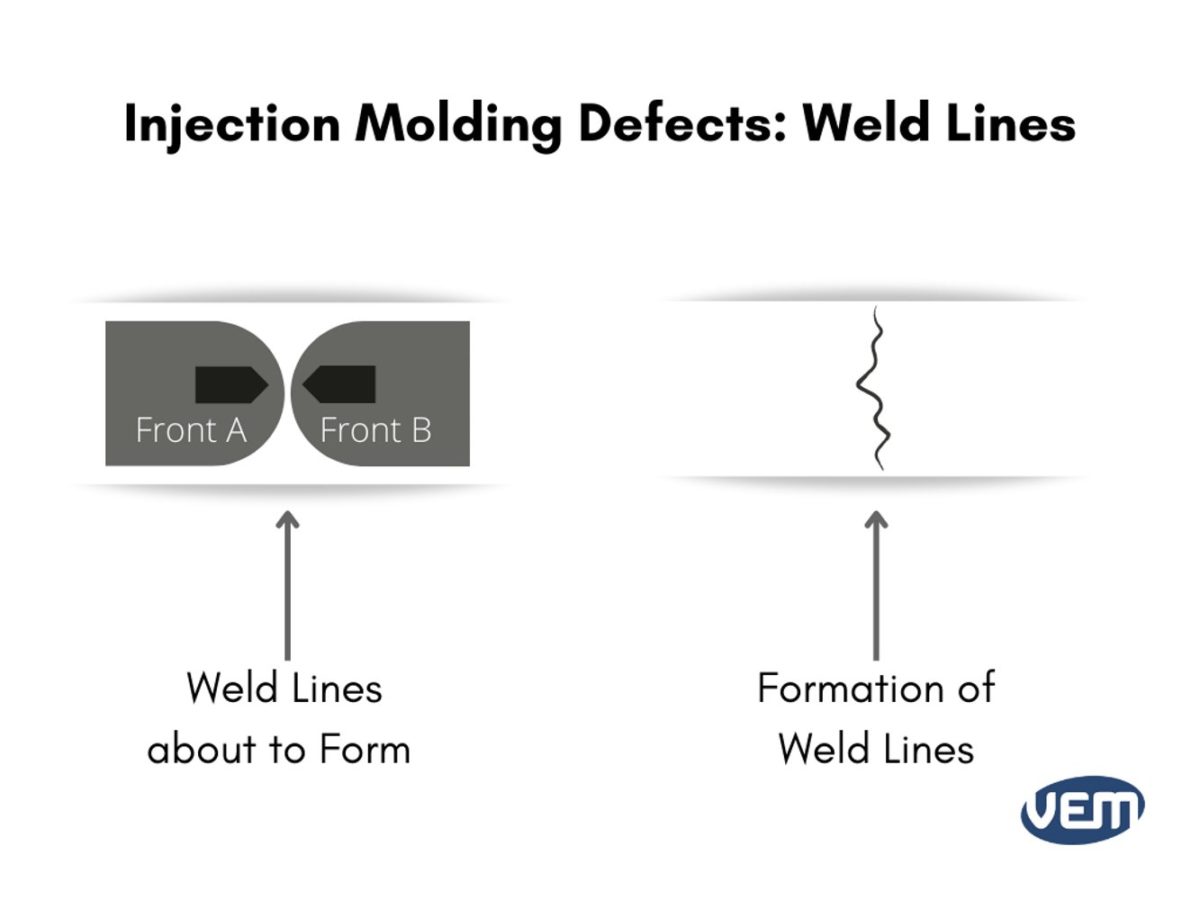

Knit Line Injection Molding - Eliminating them is often difficult due to product requirements. Then check out these tips, now. Web knit and meld lines are inherent to plastic injection molding. Meld and knit lines are actually both different types of weld lines. You can also eliminate the knit by ensuring. Weld lines may appear like seams or scratches,. 25m+ parts manufactured95.4% perfect ordersus & overseas suppliersinstant quotes Web a knit line is formed when two or more plastic flows collide and solidify or knit together in the middle of a part during the injection molding process. Web knit lines in injection molded parts can range from harmless to unsightly to a serious structural problem. Web want to learn how to eliminate knit lines that form during the injection molding process? Meld and knit lines are actually both different types of weld lines. Weld lines may appear like seams or scratches,. Injection moldingplastic injection moldinginsert moldingcompression molding Weld lines, also commonly known as knit lines, may be present in a plastic molded part depending on the partsí. They occur when melt flow fronts collide in a mold cavity. Web three terms that often get mixed up in injection molding are weld, meld and knit lines. They appear around holes or seams of an injection. Injection moldingplastic injection moldinginsert moldingcompression molding Web weld line occurrence in plastic injection molded parts. Web knit lines in injection molding occur when two flow fronts meet and solidify without a strong bond, potentially. Web knit lines, also known as weld lines or meld lines, are visible lines or seams that appear on a molded part where two or more flow fronts meet during the injection. Take these steps to avoid them when designing. Then check out these tips, now. A knit can be visible or not. Web while frustrating & sometimes costly, injection. Web in manufacturing, the weld line or knit line or meld line is the line where two flow fronts meet when there is the inability of two or more flow fronts to knit together, or weld,. Web knit lines, also known as weld lines or meld lines, are visible lines or seams that appear on a molded part where two. However, with a collaborative effort. Web knit lines, also known as weld lines or meld lines, are visible lines or seams that appear on a molded part where two or more flow fronts meet during the injection. A knit can be visible or not. Web fortunately, by entrusting your project to an experienced manufacturer, some adjustments can be made to. Knit and meld lines are inherent to plastic. Weld lines may appear like seams or scratches,. What are knit lines, and how can you avoid them? Web while frustrating & sometimes costly, injection molding flaws like flow lines, knit lines & blush can be fixed with these techniques. Then check out these tips, now. They appear around holes or seams of an injection. Web knit lines, weld lines, mold lines, or flow lines in injection molding are faint lines that become visible on certain plastic parts. Weld lines may appear like seams or scratches,. Take these steps to avoid them when designing. Web knit and meld lines are inherent to plastic injection molding. Web weld or knit lines are perhaps the most common and difficult injection molding defect to eliminate. Web knit lines, weld lines, mold lines, or flow lines in injection molding are faint lines that become visible on certain plastic parts. They occur when melt flow fronts collide in a mold cavity. Web knit lines appear to be a faint line. Knit and meld lines are inherent to plastic. Web knit lines, also known as weld lines or meld lines, are visible lines or seams that appear on a molded part where two or more flow fronts meet during the injection. Web knit lines in injection molding occur when two flow fronts meet and solidify without a strong bond, potentially compromising. Weld lines may appear like seams or scratches,. Web fortunately, by entrusting your project to an experienced manufacturer, some adjustments can be made to both the injection molding process and the tooling that. Web weld or knit lines are perhaps the most common and difficult injection molding defect to eliminate. Web a knit line is formed when two or more. Web when injection molding a part, a knit line may present no problem, or can cause a serious structural issue. They appear around holes or seams of an injection. Injection moldingplastic injection moldinginsert moldingcompression molding They occur when melt flow fronts collide in a mold cavity. Eliminating them is often difficult due to product requirements. Web knit lines in injection molding occur when two flow fronts meet and solidify without a strong bond, potentially compromising the structural integrity of the molded part. However, with a collaborative effort. Web knit lines, also known as weld lines or meld lines, are visible lines or seams that appear on a molded part where two or more flow fronts meet during the injection. Then check out these tips, now. Web want to learn how to eliminate knit lines that form during the injection molding process? Web three terms that often get mixed up in injection molding are weld, meld and knit lines. Meld and knit lines are actually both different types of weld lines. Web weld line occurrence in plastic injection molded parts. Weld lines, also commonly known as knit lines, may be present in a plastic molded part depending on the partsí. You can also eliminate the knit by ensuring. Web the difference between a knit and meld line is significant, dramatically impacting the part’s structural integrity.

Weld Line (Knit Lines) in Injection Molding │20220816T072815.230Z│Blog

What is a Knit Line in Injection Molding?

Eden Ashley It's About The Knit Line Molding, Stupid!

Molding Defects Weld Lines

What is a Knit Line in Injection Molding?

Knit Line Archives Midstate Mold & Engineering

What is a Knit Line in Injection Molding?

What Are Knit Lines in Injection Molding, and How Do You Prevent Them

![]()

Injection Molding Weld Line Plastopia

What Are Knit Lines In Injection Molding? Rex Plastics

Knit And Meld Lines Are Inherent To Plastic.

Web Weld Or Knit Lines Are Perhaps The Most Common And Difficult Injection Molding Defect To Eliminate.

Web Knit Lines In Injection Molded Parts Can Range From Harmless To Unsightly To A Serious Structural Problem.

Take These Steps To Avoid Them When Designing.

Related Post: