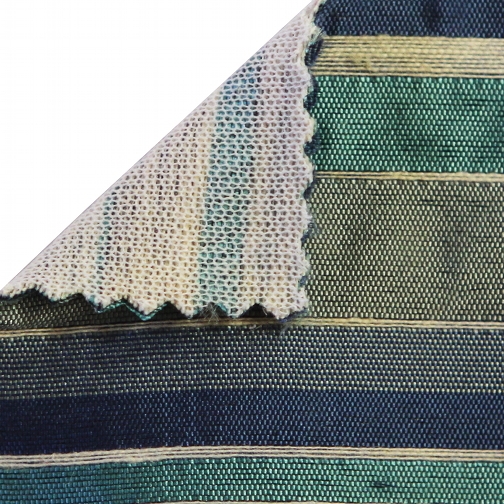

Knit Backing

Knit Backing - Web our reinforce™ knit backing is one of our most popular finishes because it adds the ideal amount of reinforcement to fabric intended for a wide variety of uses including upholstery. It greatly improves your fabric’s handling characteristics, increases its strength, and helps prevent fraying and seam slippage. Clear moisture barrier film, laminated to the back of your fabric. This backing makes delicate fabrics such as linens, silks, cottons and other types of fabrics more suitable for upholstery usage and considerably reduces seam slippage. Knit into the stitch and before slipping it off the left needle, twist the right needle behind the left and knit the same stitch again through the back loop. Web the $60 entry fee bought attendees a ball of yarn and knitting needles, fruit and vegetable snacks, hummus and pita chips, and soft drinks. Web knit backing is permanently bonded to the back of fabrics, adding body, resiliency, and durability while eliminating seam slippage. Step by step tutorial on how to kfb, knit front and back view the full blog post here: Web knit backing is a lamination process where a knitted polyester fabric is permanently bonded to the back of fabrics, which enhances the face fabric to be more durable and stronger. A knitted poly/cotton fabric backing is laminated (or bonded) to the back of your fabric to make the fabric backed product more durable, resilient, and stronger. This backing makes delicate fabrics such as linens, silks, cottons and other types of fabrics more suitable for upholstery usage and considerably reduces seam slippage. Knit backing adds the necessary body, resiliency, and strength to the silk without changing the original appearance of the fabric. Strengthen delicate fabrics to add durability for upholstery use. Web our reinforce™ acrylic upholstery backing. Our specialized processes are essential for adding strength and stability to your fabrics. It greatly improves your fabric’s handling characteristics, increases its strength, and helps prevent fraying and seam slippage. Strengthen delicate fabrics to add durability for upholstery use. Flat knit headliner 3/16 with foam backing fabric for automotive upholstery, sunroof, headlining interior lining polyester flat knit face. The process. Strengthen delicate fabrics to add durability for upholstery use. Learn how it can make a difference in your next upholstery, drapery or design project! On a knit row, work into the front and back of the next stitch: Web knit backing is permanently bonded to the back of fabrics, adding body, resiliency, and durability while eliminating seam slippage. Technologically advanced. Knit backing adds the necessary body, resiliency, and strength to the silk without changing the original appearance of the fabric. Web we offer an exclusive line of fabric finishing & backing services engineered to protect, strengthen and stabilize fabrics, trims & other woven goods. The process improves handling while eliminating seam slippage. Technologically advanced fabric finishes that provide the ultimate. On a knit row, work into the front and back of the next stitch: Learn how it can make a difference in your next upholstery, drapery or design project! You can avoid having sitting pouches on your upholstered couch by applying fabback® to your fabric. Knit backing adds the necessary body, resiliency, and strength to the silk without changing the. Web a knit backing or paper backing finish can be applied to any fabric, giving it the added strength and resiliency it needs to withstand the normal use and abuse that furniture receives. Web knitbac™ is our performance process of knit backing for upholstery fabric. Our 100% polyester backing is bonded to the fabric using a water based adhesive, increasing. Web a knit backing or paper backing finish can be applied to any fabric, giving it the added strength and resiliency it needs to withstand the normal use and abuse that furniture receives. Web our reinforce™ knit backing is one of our most popular finishes because it adds the ideal amount of reinforcement to fabric intended for a wide variety. This backing makes delicate fabrics such as linens, silks, cottons and other types of fabrics more suitable for upholstery usage and considerably reduces seam slippage. It also makes the fabric easier to cut and sew, and more resistant to tears or damage due to seam slippage. It is also known as “bar increase” because you’ll create a little visible purl. You can avoid having sitting pouches on your upholstered couch by applying fabback® to your fabric. It also makes the fabric easier to cut and sew, and more resistant to tears or damage due to seam slippage. Ideal for healthcare, nursery, and hospitality industries. Web knit backing is permanently bonded to the back of fabrics, adding body, resiliency, and durability. A knitted poly/cotton fabric backing is laminated (or bonded) to the back of your fabric to make the fabric backed product more durable, resilient, and stronger. Technologically advanced fabric finishes that provide the ultimate defense against “the everyday.” reinforce series. This fabric backing makes lightweight fabrics such as silks, cottons, and chenilles more suitable for upholstery use. Learn how knit. Web knit backing is permanently bonded to the back of fabrics, adding body, resiliency, and durability while eliminating seam slippage. It greatly improves your fabric’s handling characteristics, increases its strength, and helps prevent fraying and seam slippage. Knit into the stitch and before slipping it off the left needle, twist the right needle behind the left and knit the same stitch again through the back loop. Visit www.fabricback.com to see w. Film is naturally fire resistant. Our 100% polyester backing is bonded to the fabric using a water based adhesive, increasing stitch strength, essential for any upholstery applications, adding durability, resiliency to light to heavy weight fabrics. Flat knit headliner 3/16 with foam backing fabric for automotive upholstery, sunroof, headlining interior lining polyester flat knit face. Learn how knit backing can make a difference in your projects! Strengthen delicate fabrics to add durability for upholstery use. Web fabback ® knit backing is a process that adds strength, stability, and durability to fabric, making it suitable for use in upholstery or drapery. Step by step tutorial on how to kfb, knit front and back view the full blog post here: Web our reinforce™ knit backing is one of our most popular finishes because it adds the ideal amount of reinforcement to fabric intended for a wide variety of uses including upholstery. On a knit row, work into the front and back of the next stitch: It is also known as “bar increase” because you’ll create a little visible purl bar with it. This adds a layer of strength, elasticity, and stability to the fabric, allowing it to better resist stretching, tearing, and other damage caused by wear and tear. 10k views 3 years ago.![Fair Isle Knitting Tutorial for Beginners [+slowmo video & tips & tricks]](https://nimble-needles.com/wp-content/uploads/2022/04/backside-of-a-swatch-in-fair-isle-knitting-technique.jpg)

Fair Isle Knitting Tutorial for Beginners [+slowmo video & tips & tricks]

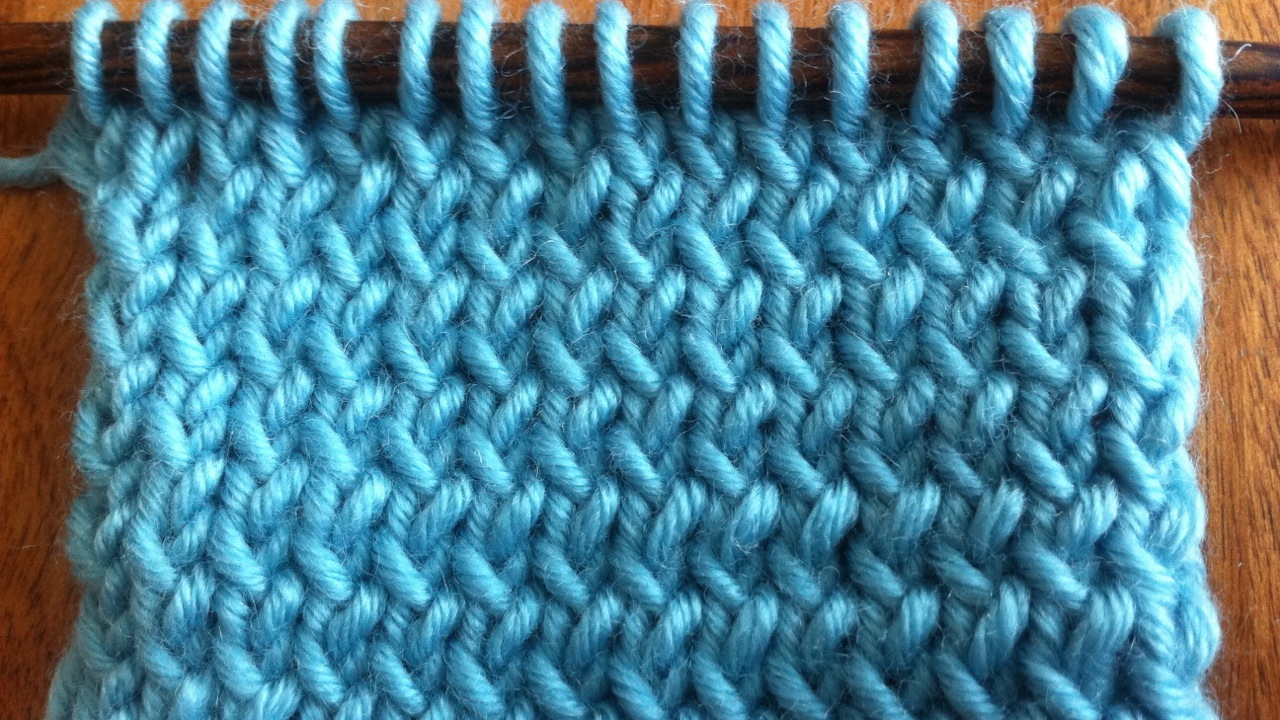

How to knit into the front and back of a stitch (KFB), photo tutorial

Knit Front and Back Increase Stitch KFB (Knitting Technique) Studio Knit

Adding A Ribbon Backing to Your Knit Button Band Knitting, Sewing basics

Knit Backing SBI Fine Fabric Finishing Athens, TX 9036751440

![How to knit two together through the backloop (K2tog tbl) [+Video]](https://nimble-needles.com/wp-content/uploads/2020/08/k2tog-tbl-knitting2.jpg)

How to knit two together through the backloop (K2tog tbl) [+Video]

How to Knit Through the Back Loop NEW STITCH A DAY

![KFB How to knit front and back [stepbystep tutorial for beginners]](https://nimble-needles.com/wp-content/uploads/2020/05/kfb-knit-front-back-on-right-needle-768x513.jpg)

KFB How to knit front and back [stepbystep tutorial for beginners]

How to Knit Through the Back Loop (ktbl) Lucinda Makes YouTube

![KFB How to knit front and back [stepbystep tutorial for beginners]](https://nimble-needles.com/wp-content/uploads/2020/05/knit-through-the-back-loop.jpg)

KFB How to knit front and back [stepbystep tutorial for beginners]

It Also Makes The Fabric Easier To Cut And Sew, And More Resistant To Tears Or Damage Due To Seam Slippage.

Helps Maintain A Clean And Sanitary Environment.

Web The $60 Entry Fee Bought Attendees A Ball Of Yarn And Knitting Needles, Fruit And Vegetable Snacks, Hummus And Pita Chips, And Soft Drinks.

1M Views 8 Years Ago Knitting Techniques With Studio Knit.

Related Post: