Injection Molding Knit Lines

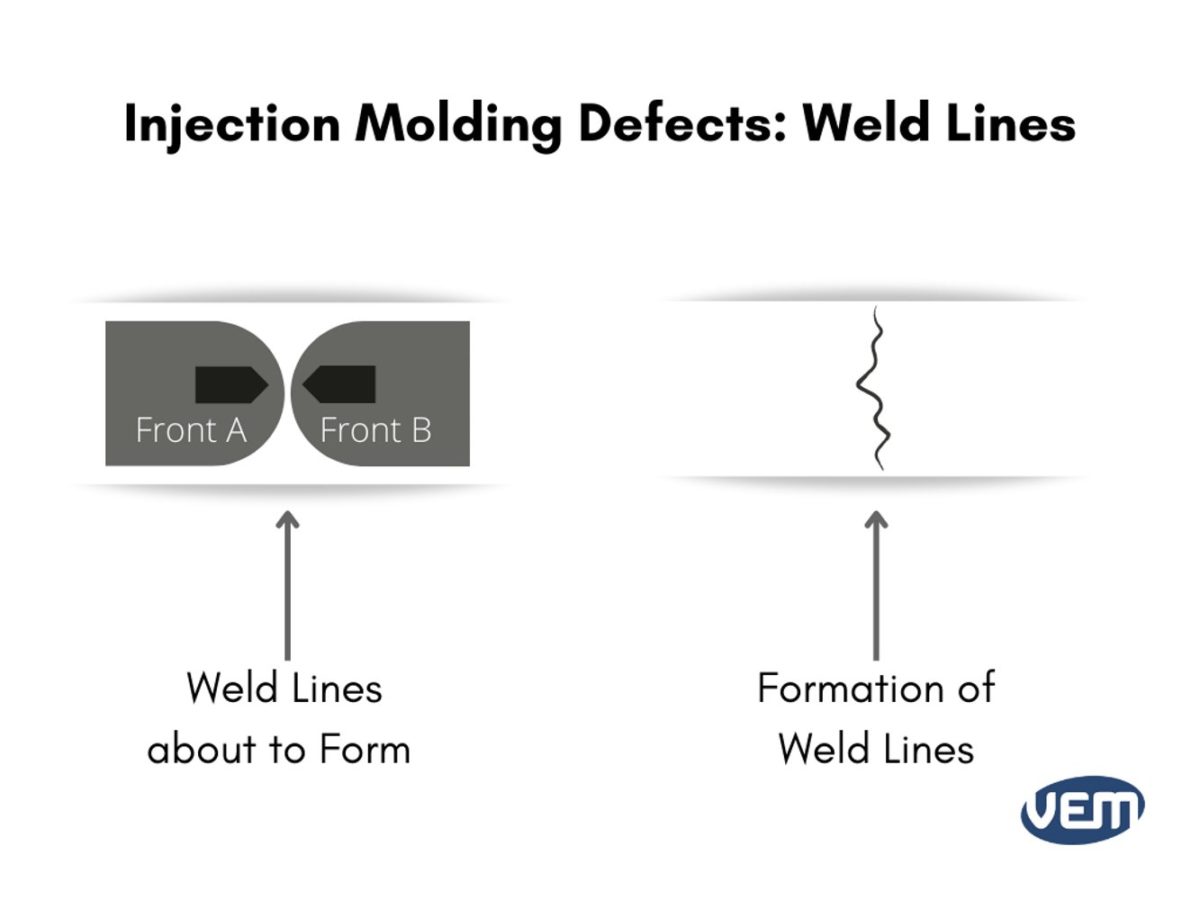

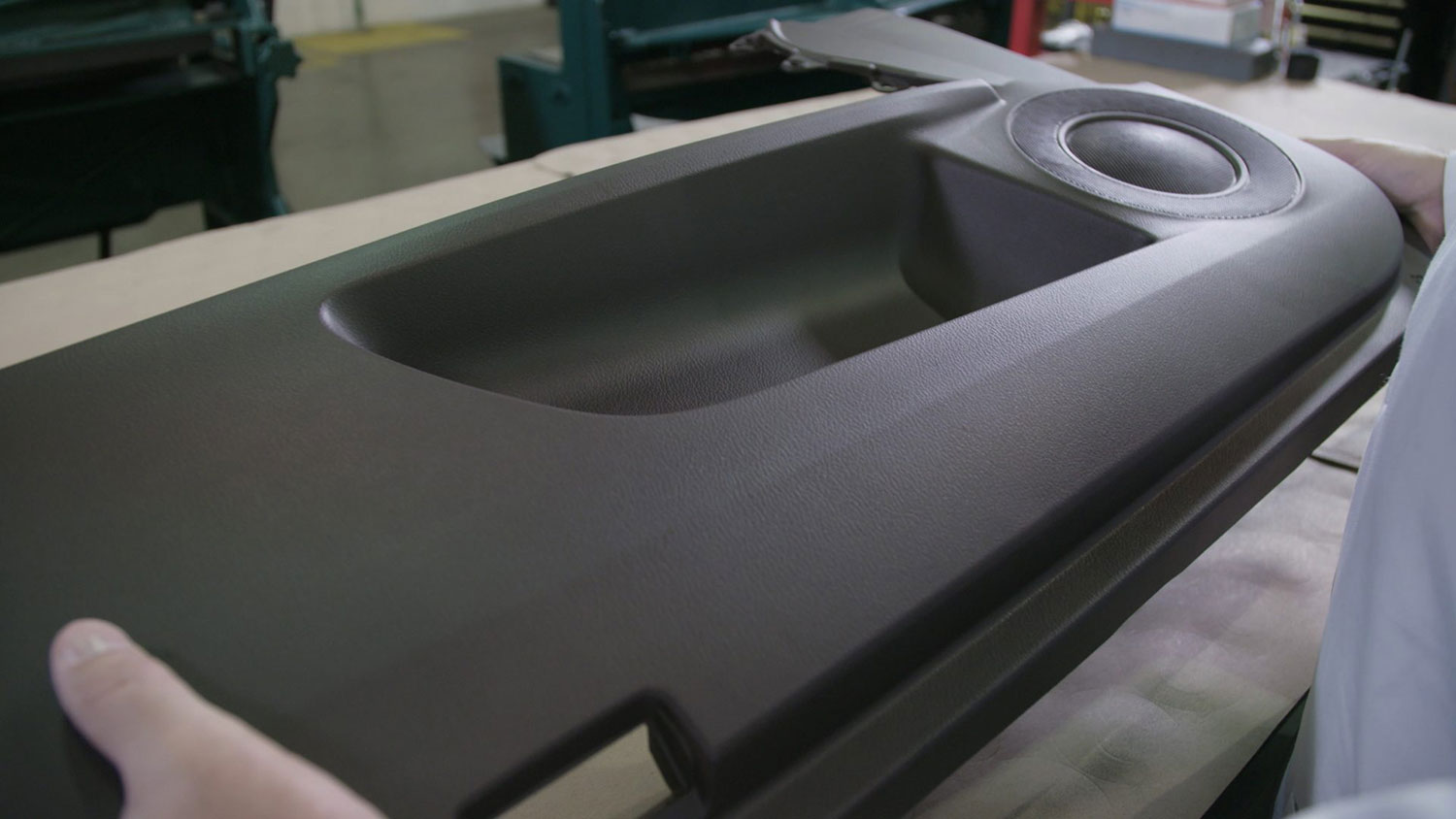

Injection Molding Knit Lines - They again get resolidified along the surface. How to eliminate knit lines. Weld lines, also commonly known as knit lines, may be present in a plastic molded part depending on the partsí geometry. Web knit lines are normal formations, which are often created during plastic injection molding along holes or seams of a mold. Let’s review what causes meld and knit line imperfections, how they’re different, and how they affect part durability. Wavy lines are another feature of weld lines. Web knit lines are formed in injection molding when two flow fronts meet in the middle of a part (a line where two sides of the plastic are “knit” together). Web knit lines, weld lines, mold lines, or flow lines in injection molding are faint lines that become visible on certain plastic parts. This article will review how and why weld lines occur, how mold gates effects weld line location and strength, the importance of material selection and the material. Meld and knit lines are actually both different types of weld lines. What are knit lines, and how can you avoid them? Web what are knit lines? Web knit lines, also known as weld lines, are a common phenomenon in injection molding where two flow fronts of molten plastic converge and solidify without bonding perfectly. Web here are 3 common injection molding flaws and how to prevent them from happening in the. Web what are knit lines? Web three terms that often get mixed up in the plastic injection molding industry are weld, meld, and knit lines. In injection molding, it is often important to maintain consistent color throughout the part. Web knit lines are normal formations, which are often created during plastic injection molding along holes or seams of a mold.. This article will review how and why weld lines occur, how mold gates effects weld line location and strength, the importance of material selection and the material. What causes knit and meld lines? Timing and temperature are significant contributing factors when it comes to flow and knit line defects. Often called “weld lines” or “flow lines”, knit lines typically appear. A poor knit line can cause only cosmetic blemishes or it can significantly weaken the structural integrity of a part. Weld lines may appear like seams or scratches, but that is not what they are. Web three terms that often get mixed up in injection molding are weld, meld and knit lines. Meld and knit lines are actually both different. When two streams of melt meet, they form a weld line, which appears as a linear mark on the surface of the molded part. Weld lines, also commonly known as knit lines, may be present in a plastic molded part depending on the partsí geometry. A poor knit line can cause only cosmetic blemishes or it can significantly weaken the. Thicken part walls to slow down the resin cooling process however be careful not to make them too thick that it causes. Think about how a resin flows through a mold. Those are knit lines, formed when two opposing flows of material join together in the mold cavity. They usually are a slightly different color than the rest of the. Meld lines and knit lines. They usually are a slightly different color than the rest of the piece, and typically occur on more narrow sections of the molded item. Web weld line occurrence in plastic injection molded parts. What are knit lines, and how can you avoid them? A knit line is formed when two or more plastic flows collide. Three terms that often get mixed up are weld, meld, and knit lines. One of the deciding factors is the resin being injected, since resins vary in their tendency to form knit lines. Change the boss or gate locations. Depending on design and material, a knit line could be no problem at all, merely a cosmetic issue, or result in. A knit can be visible or not visible. Web knit lines are formed in injection molding when two flow fronts meet in the middle of a part (a line where two sides of the plastic are “knit” together). Web three terms that often get mixed up in injection molding are weld, meld and knit lines. Web a knit line is. Here are some ways manufacturers can avoid quality issues during the plastic injection molding process: Here is a look at the differences between them, the causes of meld and knit line imperfections, and their impact on part durability. Change the boss or gate locations. Web in the plastic injection molding industry, we work with materials that are byproducts of oil. Web weld line occurrence in plastic injection molded parts. What are knit lines, and how can you avoid them? Web material selection, part design, tool design, and process parameters all also affect knit lines. Depending on the resin, resin temperature, mold temperature, and filling speed, knit lines can vary from virtually invisible to something that looks like cracks in the plastic. Web what are knit lines? Here are some ways manufacturers can avoid quality issues during the plastic injection molding process: Web depending on the design of the mould and the material being injected, a knit line may: Change the boss or gate locations. Web three terms that often get mixed up in the plastic injection molding industry are weld, meld, and knit lines. Web knit lines in injection molded parts can range from harmless to unsightly to a serious structural problem. In injection molding, it is often important to maintain consistent color throughout the part. A knit can be visible or not visible. They appear around holes or seams of an injection molded part, and some may call them “flow lines” or “weld lines”. They again get resolidified along the surface. In this blog post, we will delve into what knit lines are, how they are formed, and how you can prevent them. Web prevent flow and knit lines during the injection molding process.

Eden Ashley It's About The Knit Line Molding, Stupid!

What Are Knit Lines in Injection Molding, and How Do You Prevent Them

What is a Knit Line in Injection Molding?

Molding Defects Weld Lines

What is a Knit Line in Injection Molding?

Weld Line (Knit Lines) in Injection Molding │20220816T072815.230Z│Blog

What Are Knit Lines In Injection Molding? Rex Plastics

What is a Knit Line in Injection Molding?

Injection Mold Flaws & How to Prevent Them Flow Lines, Knit Lines, & Blush

![]()

Injection Molding Weld Line Plastopia

Present No Problem At All, Be A Cosmetic Issue, Or Cause A Potentially Serious Structural Problem.

Select Resins That Are Less Susceptible To Knit Line Formation.

Those Are Knit Lines, Formed When Two Opposing Flows Of Material Join Together In The Mold Cavity.

Meld Lines And Knit Lines.

Related Post: